Our fixing sets are designed for reliability and ease of installation. Each set includes durable components engineered to ensure a secure and stable fit, preventing any movement. With precision manufacturing and quality materials, our fixing sets are ideal for a variety of sanitary ware applications. Enjoy hassle-free installation and long-lasting, stable performance with our expertly crafted fixing sets.

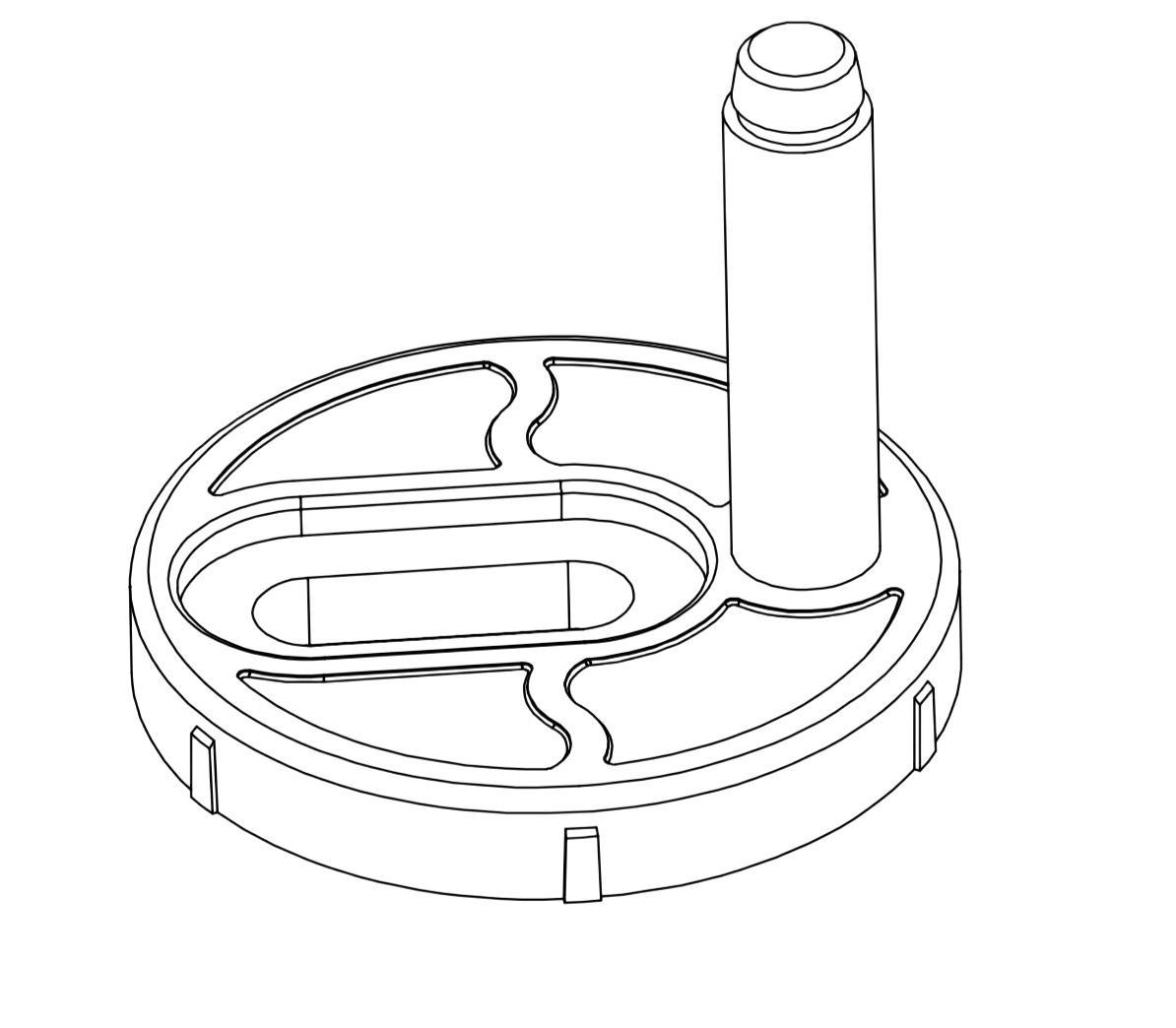

LY-HD45-02 Toilet Seat Fixing Set Kit DIY Top Fix Replacement

A DIY Top Fix Replacement Toilet Seat Fixing Set Kit is a product that allows you to replace the fixing hardware for a toilet seat. It typically includes various components such as hinges, bolts, and nuts.

The "top fix" refers to the mechanism of attaching the toilet seat from the top of the toilet bowl rather than from underneath. This type of fixing is often used when the access to the underside of the toilet bowl is limited or not easily accessible.

The kit is designed to provide all the necessary hardware to securely install or replace a toilet seat. It usually includes adjustable hinges that can accommodate different hole distances, allowing for compatibility with various toilet seat designs. The hinges are often made of materials such as metal, such as zinc alloy, which provides durability and stability.

The DIY aspect means that you can install or replace the toilet seat hardware yourself without the need for a professional plumber. This kit is typically affordable and allows you to easily replace worn-out or damaged toilet seat hinges and ensure a secure and stable attachment of the toilet seat to the toilet bowl.

Item No :

LY-HD45-02Order(MOQ) :

1000Package Included :

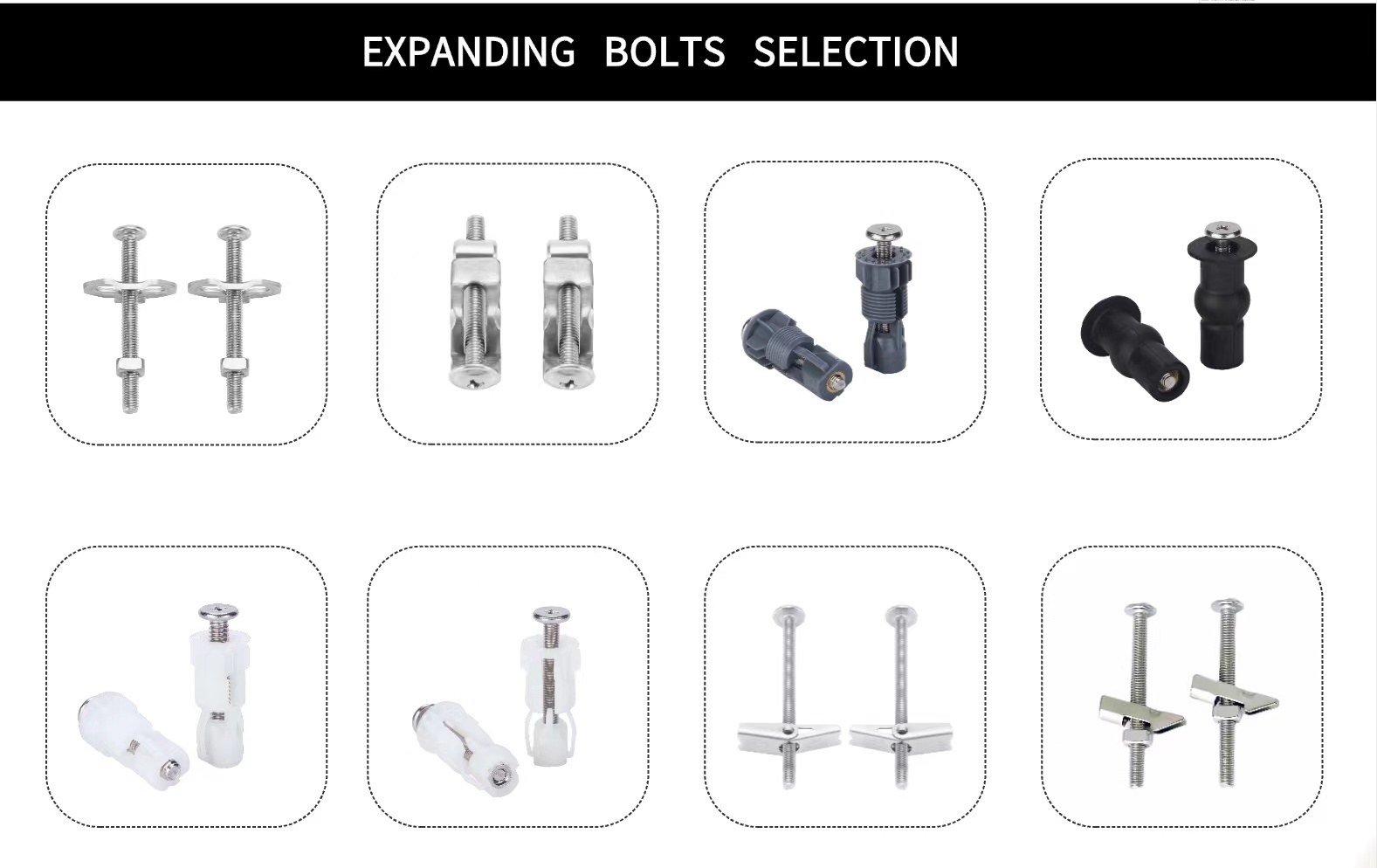

2 x cover plate, 2 x rubber washer,2 x fixing screw, 2 x anchorColor :

CustomizableShipping Port :

SHANGHAILead Time :

15-25 DAYSDiameter :

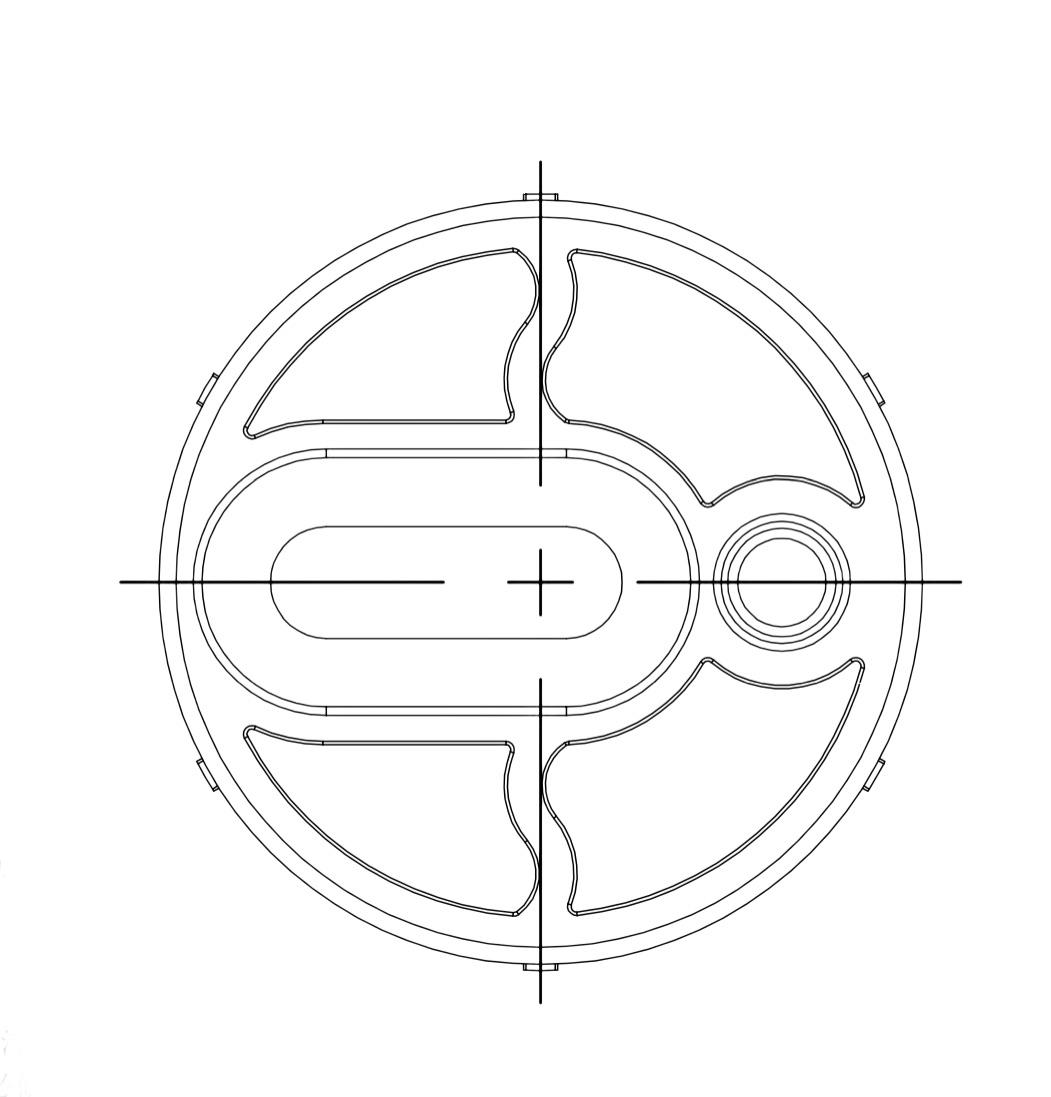

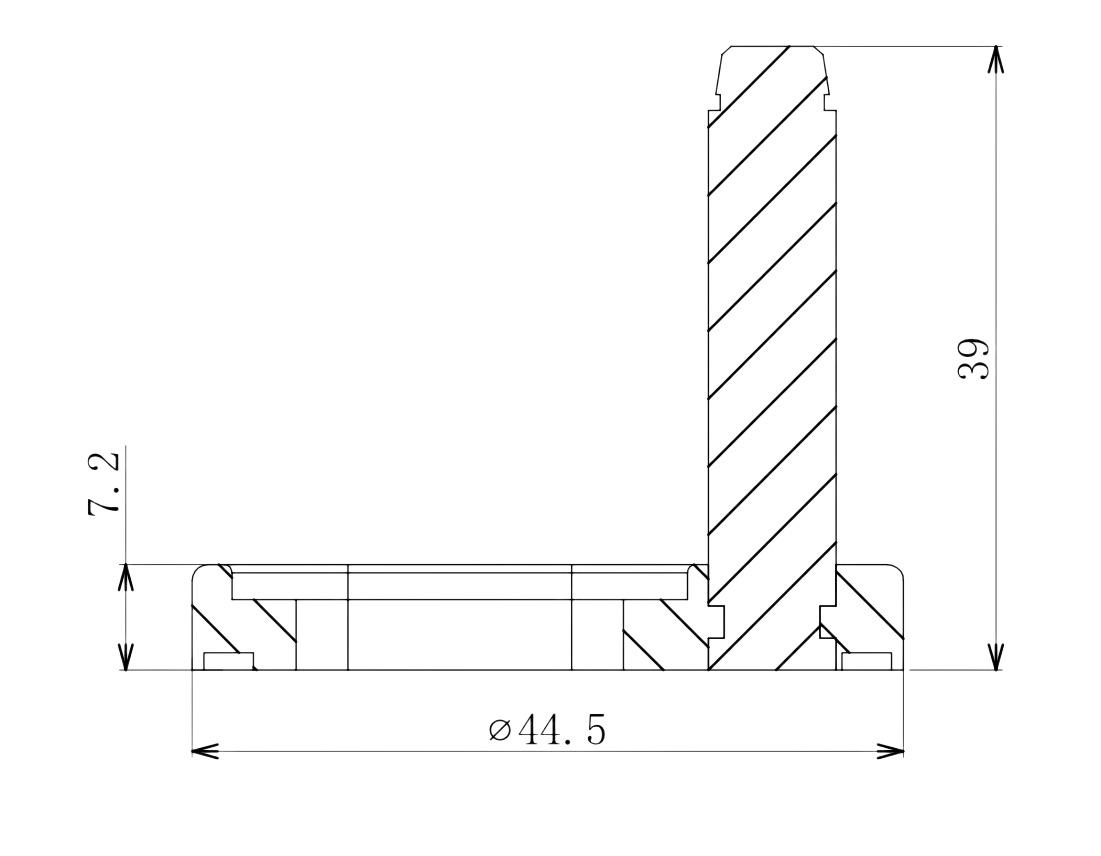

45mm,50mm,60mm

![]()

Main body: SUS304 (Stainless Steel)

Additional components: POM, PA66, Brass

![]()

![]()

| TYPE | Fixing set for toilet seat cover |

| FEATURE | Quick release, easy installation |

| Nail Tightness Test | 13000times |

| Neutral Salt Spray Test | 96 hours |

| Acetic Acid Salt Spray | 48 hours |

| Screws Tightening | 3.0-5.0 Nm |

| Hardness Of Rubber | Shore A 70±5 |

| Load Testing | 600N |

![]()

1.Smooth Base Surface: The base surface should be flat and even, without any bumps or irregularities .

2.The product's surface should be free of any burrs, sharp edges, or other defects.

3.Stainless steel rivets must pass a 10kg tensile force test; no detachment is allowed.

4.Ensure that the components and materials match as specified in the 3D drawing.

5.All products must pass quality control checks, including visual inspection and functional testing, before shipment.

6.Packing should be free of holes, broken edges and cracks.

1.Insert the bolts into the seat hinges.

2.Align the seat with the mounting holes on the toilet bowl.

3.Insert the bolts through the holes from above.

4.Secure the seat by placing washers and nuts onto the bolts and tightening them with a screwdriver and wrench.

5.Ensure the seat is properly aligned before fully tightening the nuts.

6.Snap on any provided bolt covers for a clean, finished look.

Address: No. 9, Renmin East Road, Industrial Concentration Zone, Chenbao Town, Xinghua City, Jiangsu Province

Copyright 2023 © Taizhou Longway Molding Technology Ltd All Rights Reserved. Sitemap | Blog | Xml | Privacy Policy  Network Supported

Network Supported